The Comprehensive Guide to Stamped Metal Sheets

Stamped metal sheets are an essential component in various industries, offering durability, versatility, and aesthetic appeal. Understanding what stamped metal sheets are and their applications can pave the way for businesses to harness their benefits effectively. In this article, we delve into the details of stamped metal sheets, focusing on their manufacturing processes, advantages, applications, and how Gold Eco Steel stands out as a premier provider of metal fabricators in this niche.

What Are Stamped Metal Sheets?

Stamped metal sheets are pieces of metal that have been processed using a stamping machine, which applies tremendous pressure to create a specific shape or design. This process can employ different metal types, including steel, aluminum, and copper, making stamped metal sheets incredibly versatile.

Manufacturing Process of Stamped Metal Sheets

The manufacturing of stamped metal sheets involves several steps:

- Material Selection: Choosing the appropriate metal material based on the application's requirements such as strength, weight, and corrosion resistance.

- Design and Prototyping: Creating detailed design drawings using CAD (Computer-Aided Design) software. Prototypes may be created for testing purposes.

- Tooling Creation: Fabricating the dies and molds required for stamping. This is a critical step that determines the accuracy and quality of the final product.

- Stamping Process: Using hydraulic or mechanical presses to stamp metal sheets into desired shapes and configurations. The pressure can range from several tons to several hundred tons, depending on the design specifications.

- Finishing: Applying various finishing techniques such as polishing, coating, or galvanizing to enhance durability and aesthetics.

Advantages of Using Stamped Metal Sheets

Businesses across different sectors benefit from utilizing stamped metal sheets. Here are some key advantages:

- Cost-Effectiveness: Once the tooling is created, mass production of stamped parts becomes very economical, significantly reducing per-unit costs.

- Precision and Consistency: Stamping allows for high precision and consistent quality across all units produced, making it ideal for manufacturing scenarios requiring repetitive components.

- Versatile Designs: With stamping, complex shapes and intricate designs can be achieved, allowing for creativity in product development.

- Material Efficiency: Stamping can maximize the use of raw materials, resulting in less waste and a more sustainable manufacturing process.

- Strength and Durability: Stamped metal sheets often possess superior mechanical properties compared to their non-stamped counterparts, making them ideal for structural applications.

Applications of Stamped Metal Sheets

The versatility of stamped metal sheets enables their application in a wide array of industries:

1. Automotive Industry

In the automotive sector, stamped metal sheets are utilized to manufacture parts such as body panels, chassis components, and brackets. The durability and weight-saving attributes of stamped components contribute significantly to vehicle performance and safety.

2. Aerospace Sector

Stamping is crucial in aerospace manufacturing, where precision is non-negotiable. Stamped metal sheets are used for producing fuselage components, wing structures, and assembly frames, ensuring every piece withstands rigorous standards.

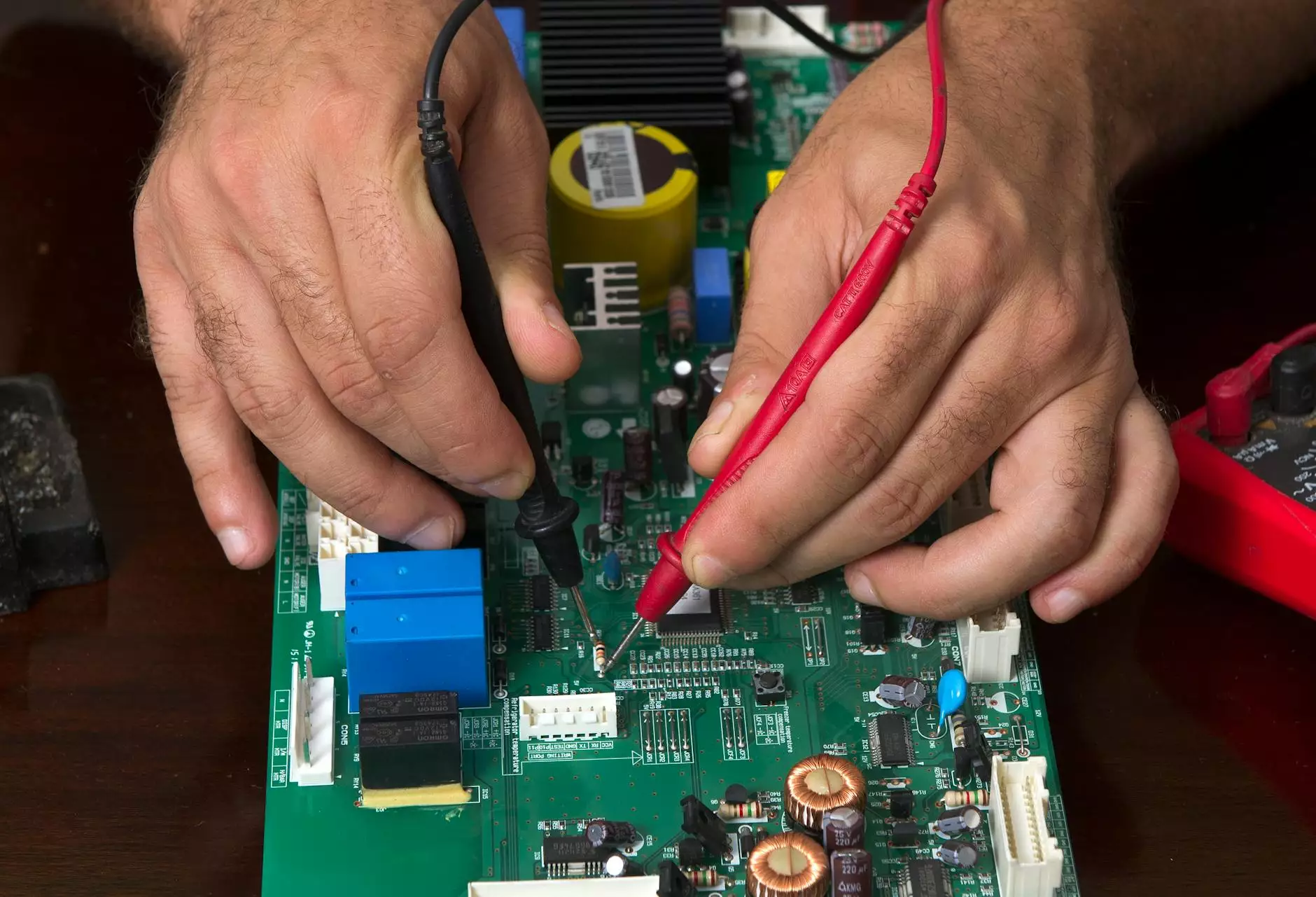

3. Electronic Equipment

Electronic devices often utilize stamped metal sheets for casings and support structures. Their reliability and ability to be produced in large volumes make them a preferred choice for manufacturers.

4. HVAC Systems

Stamped metal sheets are extensively used in HVAC components such as vents, ducts, and casings, ensuring efficient airflow and temperature regulation.

5. Home Appliances

From refrigerator panels to washing machine casings, stamped metal sheets play a crucial role in the fabrication of home appliances, improving both functionality and aesthetic appeal.

Why Choose Gold Eco Steel for Your Stamped Metal Needs?

When it comes to sourcing stamped metal sheets, partnering with a reliable supplier is paramount. Gold Eco Steel is an industry leader, specializing in metal fabricators and offering unparalleled service and quality. Here are some reasons to choose Gold Eco Steel:

- Expertise and Experience: With years of experience in metal fabrication, our team consists of skilled professionals who understand the intricacies of stamped metal production.

- State-of-the-Art Technology: We utilize advanced stamping technologies and equipment to ensure precision and quality in every product.

- Customization Capabilities: Our services cater to a diverse range of industries, allowing for custom solutions tailored to specific needs.

- Commitment to Quality: At Gold Eco Steel, quality is our top priority. We adhere to stringent quality control processes to ensure that all products meet or exceed industry standards.

- Sustainability Practices: We are committed to sustainable manufacturing practices, minimizing waste, and optimizing resource use throughout our processes.

Conclusion

In conclusion, stamped metal sheets represent a vital element in modern manufacturing, offering numerous advantages across various applications. Whether you are in the automotive, aerospace, or home appliance sector, recognizing the potential of stamped metal sheets can significantly impact your business operations and outcomes. Trust Gold Eco Steel, your dedicated metal fabricators, to provide high-quality stamped metal products that meet your needs and promote your business’s success.

Contact Us

If you have questions or require more information about our stamped metal sheets or other fabrication services, do not hesitate to reach out to us at Gold Eco Steel. Our team is ready to assist you in achieving your manufacturing goals.