DeepMould: Elevating the Standards of Metal Fabrication and Plastic Injection Molding Industry

In the rapidly evolving world of manufacturing, staying ahead of technological advancements and maintaining unparalleled quality standards are essential for long-term success. DeepMould has emerged as a trailblazer in this domain, renowned for its exceptional expertise in Metal Fabricators and operating a world-class plastic injection molding factory. Our comprehensive approach combines cutting-edge machinery, innovative design solutions, and a dedicated workforce committed to exceeding client expectations.

Comprehensive Overview of DeepMould’s Business Philosophy

At DeepMould, our core philosophy revolves around delivering unparalleled quality, fostering innovation, and prioritizing customer satisfaction. We believe that a successful manufacturing partnership is built on transparency, precision, and continuous improvement.

With decades of experience, our team of skilled technicians and engineers leverage the latest technologies to produce high-precision metal components and sophisticated plastic parts. Our integrated approach ensures seamless project execution from conceptual design to final product delivery.

Why Choose DeepMould's Metal Fabricators

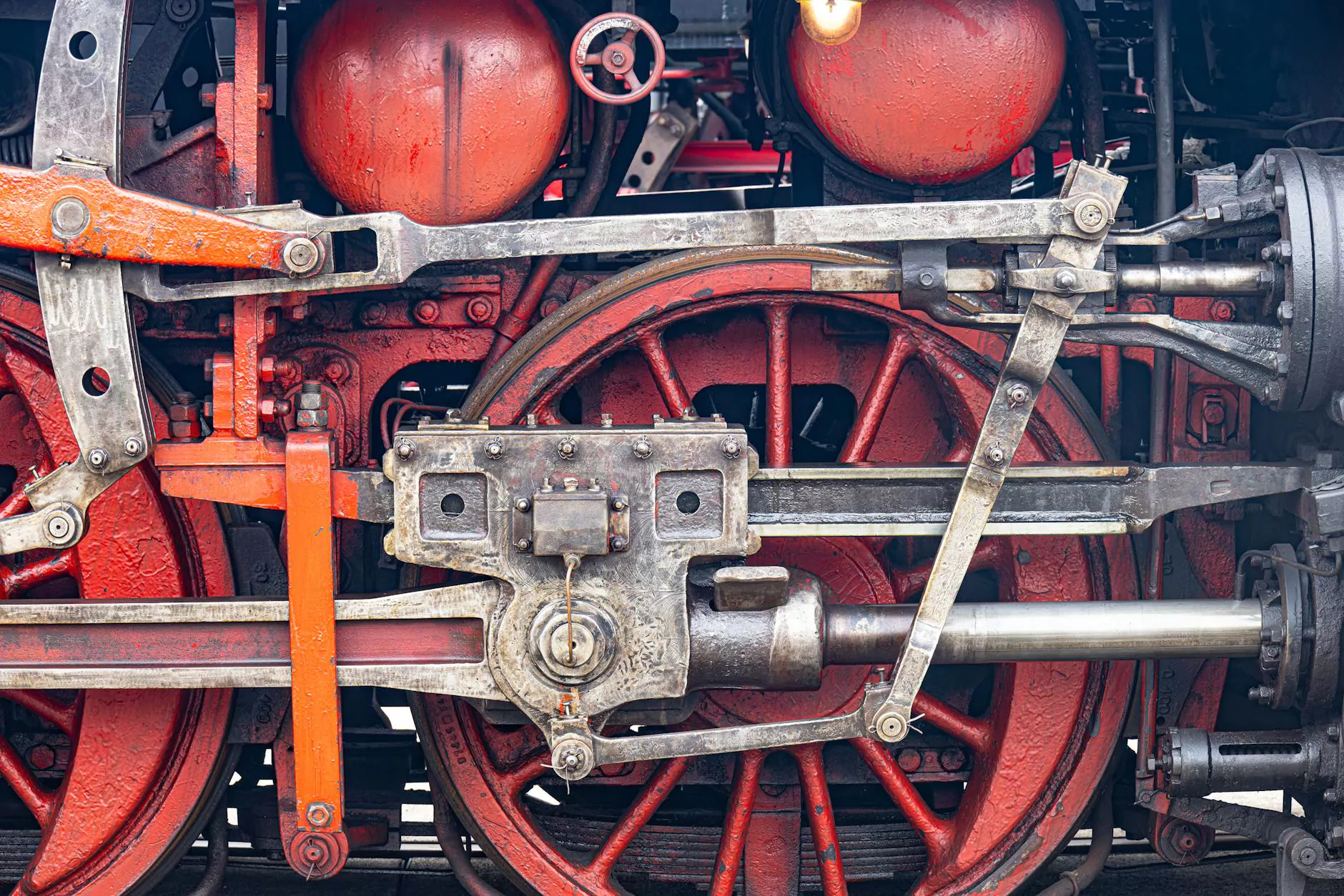

DeepMould’s metal fabrication division combines advanced techniques such as CNC machining, laser cutting, welding, and finishing to create durable, precise, and innovative metal solutions. Our capabilities extend across various metals including steel, aluminum, copper, and brass, allowing us to serve a diverse range of industries such as automotive, aerospace, electronics, and industrial machinery.

State-of-the-Art Metal Fabrication Equipment

- High-precision CNC machines for complex machining tasks

- Laser cutting systems for accurate and efficient metal shearing

- Robotic welding stations ensuring consistent weld quality

- Surface finishing tools for polishing, anodizing, and coating

These tools empower us to produce components with tight tolerances, superior surface finishes, and structural integrity, meeting even the most demanding specifications.

DeepMould’s Innovation in Plastic Injection Molding Factory

Our plastic injection molding factory stands at the forefront of the plastics industry, integrating state-of-the-art machinery with innovative design and process optimization. This facility enables us to manufacture a wide array of plastic parts with exceptional precision, consistency, and efficiency.

Key Capabilities of Our Plastic Injection Molding Facility

- Multiple injection molding machines ranging from small to large tonnage for diverse product sizes

- Advanced mold design and fabrication for complex geometries

- Automatic material handling systems for high-volume production

- In-line quality inspection and testing to ensure defect-free products

- Rapid prototyping and short-run production for product development

Our factory’s versatility allows us to produce everything from simple caps and containers to intricate electronic housings and medical devices, making us a trusted partner for global OEMs and small startups alike.

The Edge: Why DeepMould is the Plastic Injection Molding Factory of Choice

Choosing the right plastic injection molding factory can significantly impact product quality, delivery times, and overall costs. DeepMould offers unmatched advantages:

- Unmatched Quality Control: Rigorous inspection procedures at every stage ensure defect-free parts, adherence to standards like ISO9001, and ISO13485 for medical-grade products.

- Cost Efficiency: Our optimized manufacturing processes and bulk procurement strategies reduce production costs without compromising quality.

- Fast Turnaround: State-of-the-art equipment and streamlined workflows enable rapid prototyping and quick order fulfillment.

- Customization and Flexibility: From engineering support to mold design, we adapt our services to suit unique project requirements.

- Global Reach: Our extensive logistics network guarantees timely delivery to clients worldwide, supporting diverse markets and industries.

DeepMould’s Role in Advancing Industry Standards

As leaders in the Metal Fabricators sector and operators of a premier plastic injection molding factory, DeepMould consistently pushes the boundaries of technological innovation and sustainable manufacturing. Our commitment to environmental responsibility includes adopting eco-friendly materials, recycling waste, and reducing energy consumption during production.

Furthermore, our R&D department diligently explores new materials, mold designs, and production techniques, ensuring our clients benefit from the latest advancements in manufacturing technology.

Industries We Serve

The versatility and quality of DeepMould's manufacturing solutions enable us to serve a broad spectrum of industries:

- Automotive: Precision metal parts and durable plastic components for vehicles

- Electronics: Enclosures, connectors, and intricate plastic parts for consumer and industrial electronics

- Medical Devices: Complex, compliant plastic and metal parts for medical equipment

- Aerospace: High-strength, lightweight metal and plastic components for aerospace applications

- Industrial Machinery: Heavy-duty metal fabrications and precision plastic parts essential for machinery

- Consumer Goods: Custom-designed plastic products for everyday consumer applications

Our Commitment to Quality, Innovation, and Sustainability

DeepMould is driven by a relentless pursuit of excellence. Our quality management systems ensure every product leaving our facility meets or exceeds international standards. Innovation is embedded in our culture—constant investment in new technology and methods to improve efficiency and product performance.

Sustainability remains a key priority. We actively implement practices that reduce environmental impact, such as utilizing recyclable materials, energy-efficient machinery, and waste reduction programs.

Partner with DeepMould for Your Manufacturing Needs

When you choose DeepMould, you partner with a dedicated team that values quality, efficiency, and innovation. Whether you need high-volume production, custom prototypes, or complex metal fabrications, our comprehensive services provide an all-in-one solution. Our transparent communication and commitment to timelines ensure your project is completed flawlessly.

Contact us today to learn more about how our metal fabricators and plastic injection molding factory can bring your product ideas to life with precision, quality, and efficiency.